Automatic doy bag packing solution for 25-500gram nuts

Machine introduction:

This unit machine including one set ZL20-1.6L multi heads weighing machine for weighing two different product, one set ZL8-230 rotary bag taking opening filling sealing machine, one set DT5 bucket elevator and one set safety platform and ladder. The main machine are control by siemens PLC and operate by touch screen .Adopt famous Electrical accessories. High automation and easy to operate. Widely use by the different industry like Daily chemical, food, chemical, and etc.

Machine details:

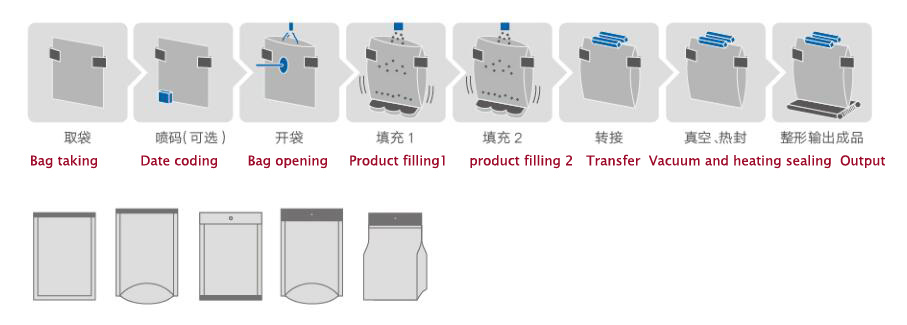

1, Model of ZL8-230 Rotary packing machine(doy packer with zipper)

Function and characteristics

1、操作簡單,採用西門子先進的PLC,配合觸摸屏和電控系統,人機界面友好。

2、變頻調速:本機採用變頻設備,可根據生產實際需要在範圍內調節

3、自動檢查:無袋或開袋錯誤、無填充、無封口。袋子可以重複使用,避免浪費包裝材料和原材料。

4、安全裝置:氣壓異常停機,加熱器斷線報警。

5、袋子的寬度可通過電動機調整。按下控制按鈕可以調整剪輯的寬度,操作簡單,節省時間。

6、可與玻璃安全門配套使用。同時,它可以防止灰塵。

7、採用塑料軸承,無需加油,污染少。

8、使用無油真空泵,避免在生產中污染環境。

9、The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

10、Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food

11、With different feeders changed to pack solid, liquid, thick liquid, powder and so on

12、The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on

Preformed bag made by film and paper.

產品規格

| 模型 | ZL8-230 |

| 工作崗位 | 八個工作崗位 |

| 小袋材質 | Laminated film |

| 小袋圖案 | Doy packer with zipper ,pillow bag |

| 小袋尺寸 | W:100-230mm L:150-350mm |

| 速度 | 10-35pouches/min(The speed depends on the product status and filling weight)) |

| 重量 | 1400KGS |

| 電壓 | 380V 3相50HZ / 60HZ |

ZL20-2.5L multiheads combination weighing machine

適用範圍:

It is suitable for high-speed weighing of a single material, formula mixing of multiple materials: the longest material is 60mm, and the single material is less than 60g, such as instant oatmeal and mixed nuts.

特徵:

The High-speed mode can be used for a single material;

The Weight Of the mixture can be compensated by the operation of the last material;

Using High-precision,high-standard special sensors;

Intelligent Fault Alarm prompt, maintenance is more convenient;

High-speed synchronous discharge function, effectively prevent material blockage;

The Highly integrated modular design adopts CAN bus technology;

Modbus industry standard communication protocol, realizes the combination of the combination scale and the packaging machine interface;

Other functions and features of the same generation model;

For Viscous Materials, anti-stick measures such as 60° chassis and Teflon coating can be used.

Mechanical Characteristics And product characteristics:

Separate Upper Hoppers are used for a variety of mixed formula materials;

Adopt independent main vibration machine to control the feeding thickness of different materials respectively;

The Integral Chassis and middle seat enhance the rigidity and strength of the machine, making the weighing more accurate;

The Chassis And chute adopt compatible design. When weighing a single material, it can be replaced with a double-port unloading tray, which can be equipped with a double-packing machine;

The Unified Design standard and the mold making process make the interchangeability of each part stronger.

Thestable Aluminum shell structure makes the hopper run more stably and the readings are more accurate. The integral chassis and the middle seat enhance the strength of the machine, making the hopper's stabilization time shorter;

產品規格:

| 模型 | ZLJ20-2.5L |

| Code | A20-2-2 |

| Target weight | 10-1000gram |

| 準確性 | X(0.5) |

| Maximum speed | 65B/M (Mixed product) /100B/M Single product |

| 體積 | 2.5L |

| Touch screen | 10.4' |

| Optional | Dimple Plate/Timing Hopper/Printer/Reject Device |

| 驅動模式 | Step motor |

| 功率 | 220V/2000W/50/60HZ 16A |

| Packing dimension | 1920*1650*1620 |

| 機器重量 | 850kg |