介紹 :

This line is special design for automatic feeding the bulkgraunle product bagging in to 25kg and 50 kg plastic .According the client requirement we also need offer the automatic conveying and palletizing line .The seller completed the design, manufacturing and supply of the production line in strict accordance with the technical requirements and combined with its own packaging line design experience in the sugar industry.

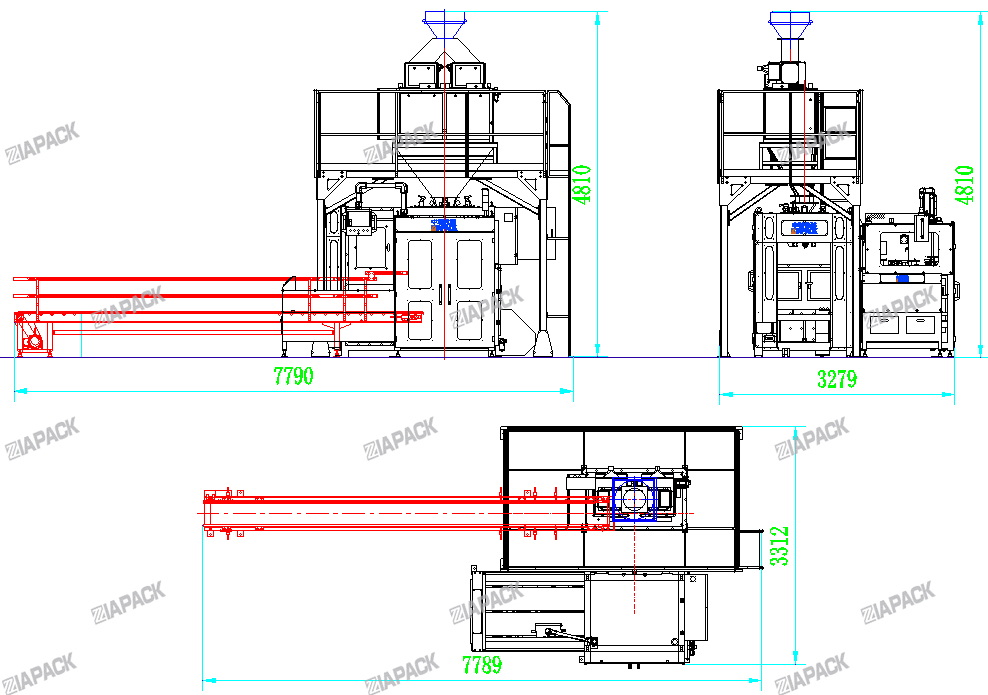

ZL25K-S Automatic double buckets gravity scale system

Principle :

This scales are composed of mechanical components and sensors of the weighing system and a weighing control instrument system. Main machine frame and material contact parts made by sus304.Including vibrating feeding for accuracy feeding and Fast feeding by valve discharge .Install with Mettler Toledo weighing sensor .The whole process of feeding, weighing and unloading loose bags is automatically controlled and self-locking.

特徵:

1,Equipped with a standard cabinet,Main electric are China famous brand

2,All equipment is equipped with local operation columns, and the packaging machine is equipped with on-site local control display panels.

3,The weighing box adopts a frame structure, which is stable as a whole and has good sealing performance. The sensors are fixed on the frame of the weighing box. Three weighing pressure sensors per scale are fixed on the frame of the weighing box. It has an independent cover, which is dustproof and anti-collision.Equipped with two dust removal interfaces and breathing holes.

4,The fast discharge door of the weighing hopper adopts a 45º tapered half-open material bottom door.The discharging speed is very fast, and the vibration generated by the cylinder will not affect the weighing accuracy.

5,All mechanical transmissions use dust-proof bearing transmission, and there is no sliding friction between metals.

6,All doors on the scale body are well sealed and there is no dust leakage.

7,All bolts and nuts inside the weighing box are protected by steel wires and cotter pins. (Use a lock nut or drill a hole at the end of the screw, and then thread it with stainless steel wire)

8,The overall external wires and air pipes are all made of closed stainless steel tubes, which are neat and beautiful. There is a dust removal interface on the scale body

9,Parts in direct contact with the material are all made of stainless steel304 and polished

Parameter setting

| 模型 | Net weight sensor type electronic scale (double scale) |

| Feeding method | Gravity blanking |

| 材料 | Material contact surface304 stainless steel, frame protection painted steel |

| 耗氣量 | ~200NL/min |

| power | ~2.0kw |

| Weighing capacity | ≥600 bags/hour |

| Set weighing value | Net weight 25-50kg/bag |

| 測量精度 | ±0.1% |

| load cell | 梅特勒托萊多 |

ZLZD750 AUTOMATIC BAGGING MACHINE

機組由儲袋倉、取袋整理裝置、裝袋機器人、夾袋卸袋裝置、推袋裝置、袋口引導裝置、真空系統、控制系統等組成。

特徵

1).對包裝袋適應性廣。包裝機採取袋方式,即從備袋倉取出包裝袋,進行居中定位,將包裝袋向前送出,袋口定位,進行預開口,裝袋機械手將刀插入袋口打開袋口,然後進行裝袋。

2).裝袋機械手臂採用伺服馬達驅動,相較於大多數其他廠商的氣動機械手具有速度快、裝袋平穩、無衝擊、使用壽命長等優點。

3).夾袋卸料裝置在夾袋口處設有兩個接近開關,用於檢測包裝袋口是否完全夾緊以及袋口是否完全打開。確保包裝機不會誤判,不會將物料灑落在地面上,提高了包裝機的使用效率和現場操作環境。

4).包裝機的參數設定均在觸控螢幕上完成。人機友善的觸控螢幕操作介面,可全面監控整機的運作狀態。自動故障顯示及處理方法提示,使維護人員能夠在最短的時間內處理故障。

5)電磁閥等氣動元件以及觸控螢幕、稱重儀表等精密產品均採用密封安裝,無外露,適合在多塵環境下使用,保證了設備擁有較長的使用壽命。

6)包裝機所有控制元件、執行元件均採用國內外知名公司產品,確保設備長期穩定可靠運作。

7)具有故障自診斷功能和聲光警報系統,對出現的任何問題及時報警。

8)簡潔、方便的操作平台,方便操作人員對機器進行操作與監控。

技術參數:

包裝能力600袋/小時

控制方式 可程式控制器(PLC)

材質:物料接觸面採用304不鏽鋼,框架保護採用304不鏽鋼等。

Set weighing value Net weight 30kg/package

空氣消耗量~600NL/min

電源AC 380V 50Hz~15kw